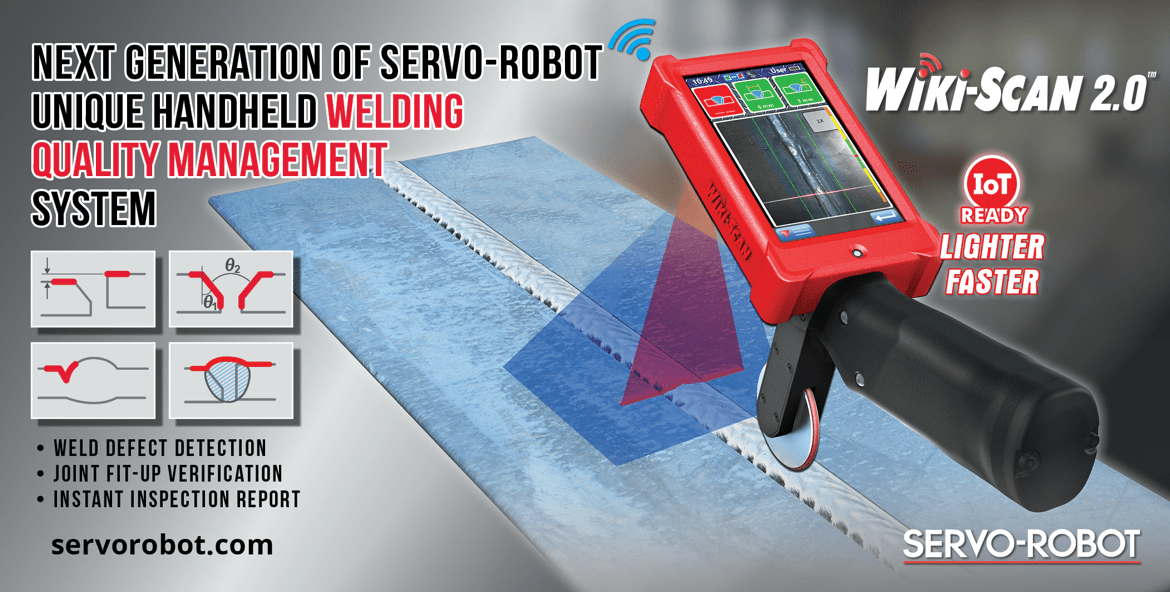

Next generation handheld welding quality system

We provide innovative and revolutionary products for companies.

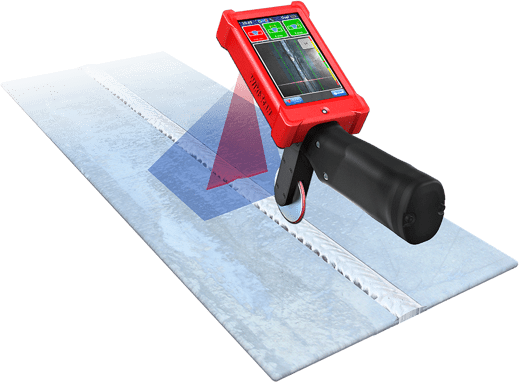

Wiki-Scan is a laser based handheld wireless system, improving the reliability of the welding inspection process. It can measure part fit-up prior to welding to insure that the joint preparation is suitable within procedure requirements. When using the WiKi-SCAN, a 3D scan of joints and weld beads are measured for a variety of features including size, porosity and undercut. These results can be augmented with a picture of the weld, voice recording and comments saved directly to the WiKi-SCAN. All records can be filtered by date, and if the weld fulfilled the standards and tolerance limits set.

- Accurate inspection of weld joint preparations

- Ensure the reliability of your welding process

- Reduce redundant inspection operations, unneeded repairs, and overwelding

- Shorten inspection time and save costs

- Comprehensive immediate objective reporting and wireless communication allow efficient data management and quality control

Benefits

- Objective results and improved reliability

- Immediate measurement results with laser-based inspection

- Automatically created inspection reports

- Real-time viewing for rapid evaluation of a joint or a weld

- The weld inspection record can be sent through Wi-Fi to anywhere in the world

- Fatigue critical features such as toe angle, undercut, and cracks can be quickly measured

- Over welding can be quantified so excessive welding time, consumable and energy usage can be reduced thus saving money

- Can inspect any weld the operator’s hand can reach

The WiKi-SCAN makes it easier to determine the size and number of defects and compare them to the applicable welding standard. Some of the many benefits of the WiKi-SCAN include the ability to eliminate inaccurate and unrepeatable inspections, determine the amount of over welding to help save money, and allow the ability to the weld while the part is hot.

This new technology will speed up the inspection process and verify if welds and repairs are done correctly per the applicable Welding Standard.

The Wiki-SCAN welding inspection system is designed to be used in the field to improve the reliability and speed of inspections in manufacturing industries.

Results

- Quality assessment

- Go/NoGo status

- SPC data

- Welder skill assessment

- Permanent record (photo, file, report & database)

Includes

- Wiki-Scan Wireless Weld Inspection System

- Wiki-Scan Battery 21Wh (2 batteries)

- Wiki-Scan Battery Charger

- Wiki-Scan Verification Block

- Wiki-Scan Earphones

- USB Cable

- Carrying Case

- Manual and Software on USB Key